3D Printing and delivery of components

We print your part from plastic or fiber-reinforced plastic with FDM 3D process. If you already have a ready 3D model and are look for a reliable partner, we can support you. We can process all common file formats (preferably STL and STEP). Send your 3D file by e-mail to info@lv-tech.eu, tell us the requested quantity, as well as the desired material and we will make you a non-binding offer. We will check your design, produce the parts with our printing processes and deliver them to the location of your choice.

All-round package

We accompany you step by step from your design idea to the finished 3D component. If you need help in creating or optimizing a CAD design, we can support you as well. The possibilities of 3D printing allow us to think radically and find new ways of realizing your idea during the development process. We would be pleased to contribute with our years of experience in the CAD field also to your project. Additionally, we answer expertly all your questions regarding materials and costs.

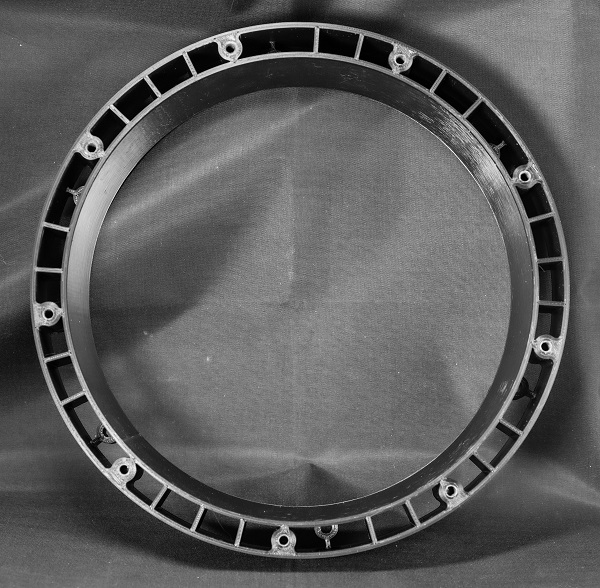

Design optimization

We can adapt your 3D models to achieve an optimal topology, providing maximum stiffness with minimum weight. We redesign the part, considering all boundary conditions and stress restrictions, to reduce the material consumption while still achieving maximum performance characteristics. Furthermore, we can recommend as well the most adequate 3D printing material for your application. An optimized for 3D printing component has many advantages in comparison to a solid part, for example:

material savings

shorter printing times

lower production costs

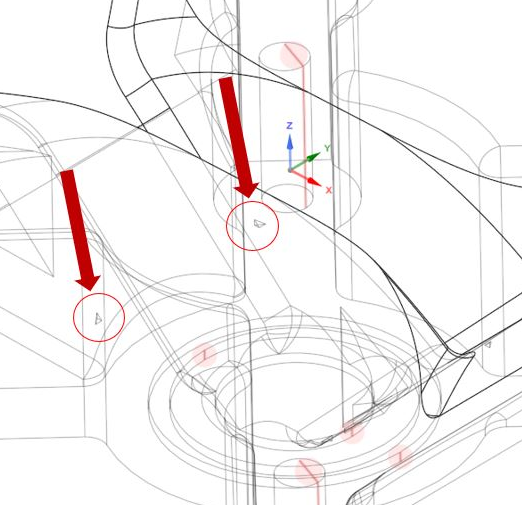

Checking and repairing corrupted 3D models

We check the geometry of your component for printability. If necessary, we can automatically or manually repair the faulty 3D files. There are many reasons for the occurrence of faulty 3D files. Sometimes the design guidelines and properties of the materials or the surface orientation are not properly considered. In such case, the component could be usually printed, however it could soon deform or break under load conditions.

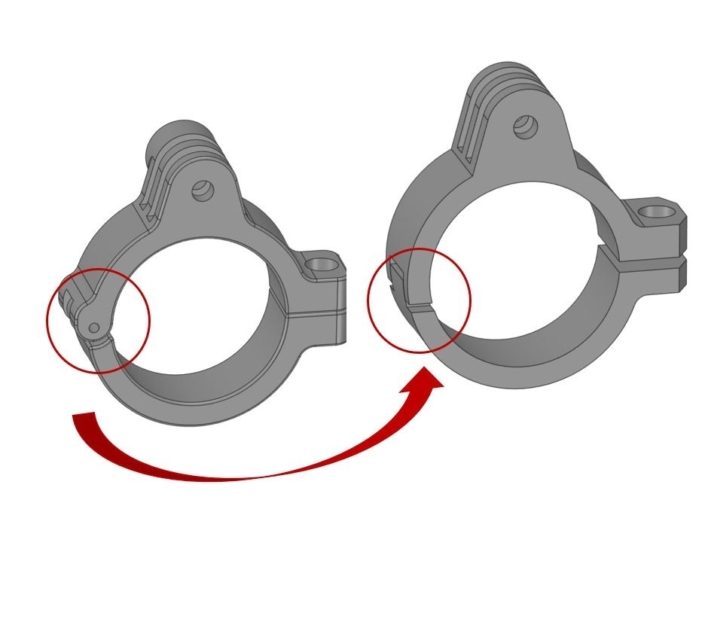

Reduction of assemblies

We can check your assembly and if possible and requested we can help you to reduce the number of the component parts. The complex geometries within assemblies are generally a challenge for the conventional methods, as all the parts of the assemblies must be properly joined together. With the additive manufacturing, we can integrate functions, so that fewer individual parts are needed. With our support, the assembly could be reduced to a single component and the manufacturing to one print operation. The consolidation of assemblies has many advantages: it is cost-effective, the printing times are shorter, the supply chain is optimized and further assembly costs are saved.

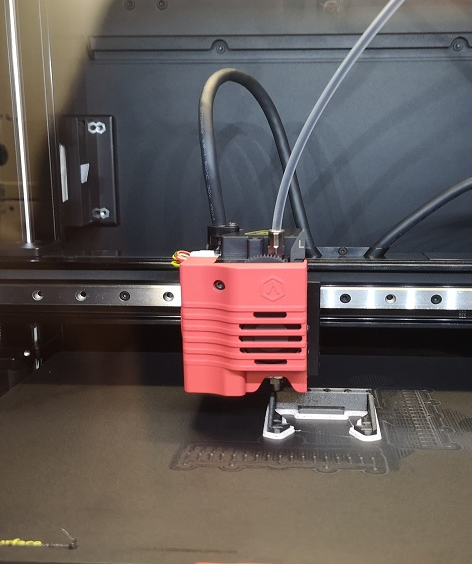

Prototype production

We can help you quickly accomplish your idea into a working prototype. The possibility to manufacture a prototype through 3D printing is essential as part of the development process. Even geometrically complex prototypes could be precisely and accurately produced using industrial 3D printing. This is normally a very cost-consuming procedure using the traditional manufacturing processes. The advantages of 3D printing in prototyping over other manufacturing processes are numerous:

Quick manufacturing of your prototypes

Cost-effective manufacturing

Accurate reproduction of even very complex parts

High flexibility during the manufacturing process

Adaptability of part shape

Creation of master models for simple castings

3D printing for spare parts

You send us the 3D model of the spare part and we print it in a few hours. If necessary, we can redesign your spare part with CAD tool and customize it according to your requirements. 3D printing of spare parts is a cost-effective solution for low-volume production. 3D printing is the best solution for the reproduction of original spare parts, that are no longer produced. Manual reconstruction of spare parts is a labor-intensive process, yet it enables a very reliable 3D model. Especially for special machines where spare parts are hard to find, manual reconstruction is the fastest and most cost-effective solution.

Small-batch series

Our 3D printing service enables small batch production. The advantages of producing small batches with 3D printing over traditional methods are many: production is faster and usually not so expensive, complex geometries can be printed and assemblies can often be reduced to just a few components. The 3D printing models can be easily individualized, e.g. with logos or serial numbers. With the diverse choice of materials and the possibilities for customization of the components, many production requirements can be met quickly and cost-effectively.

Contact

Phone:

+49 176 46780305

E-mail:

info@lv-tech.eu